Intermittency is a well-known problem when it comes to renewable power. The wind does not blow consistently, nor do the sun’s rays reach Earth’s surface with regular intensity. Clouds get in the way, and the march of the seasons introduces additional variation.

Most of the talk concerns there not being enough wind or sunshine. But countries like Denmark with well-established wind-power capacity face many days where there is too much potential energy. Currently the only solution is curtailment, where utilities providers restrict power production for fear of overloading power grids.

“The important thing is to maintain consistent temperature and pressure while the production rate varies.”

– Pat Han, Technical Director at Skovgaard Energy.

Electrolysers prevent lost opportunities

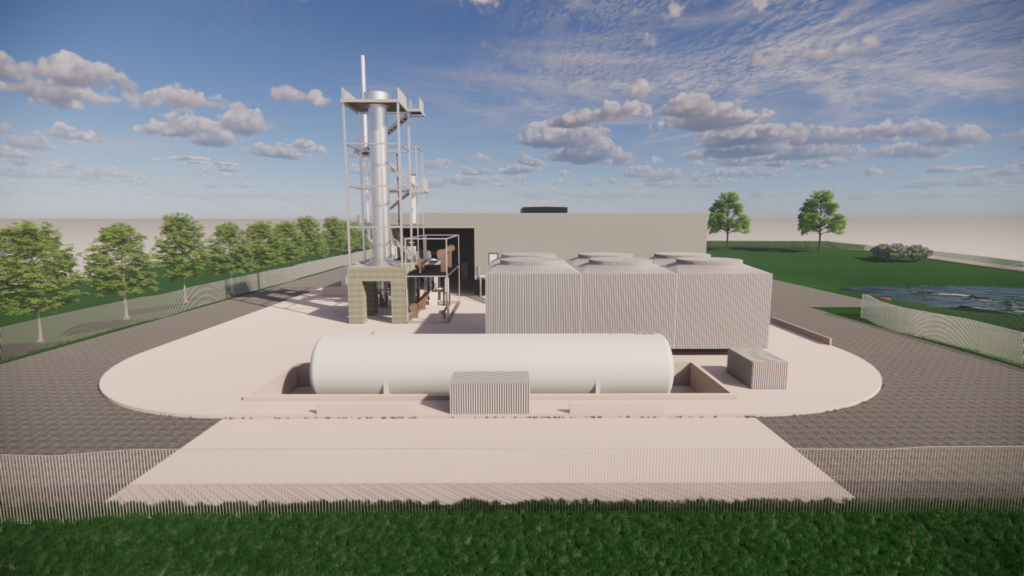

This curtailment represents a huge lost opportunity to generate, use and store power, which is one of the main reasons that Skovgaard Energy has just commissioned Nel to supply its tried-and-tested alkaline electrolyser technology for a Danish-government-funded pilot project at Lemvig in western Jutland, Denmark. Topsoe is the ammonia-technology provider, with Vestas wind turbines supplying the power.

The electrolyser stack will form part of a dynamic green-ammonia plant, the first of its kind and powered by six wind turbines. An additional 90 hectares of photovoltaic arrays are currently under construction. Any electricity these installations produce that is not required by the power grid will be redirected for use in the dynamic plant, whose ammonia can go on to make fertiliser or be burned as a zero-emissions fuel.

Conventional ammonia production relies on large amounts of natural gas fed into a plant at a consistent rate. Green-ammonia production follows a different chemical process, with hydrogen coming from water electrolysis. This is then combined with nitrogen.

Adaptability is key

As renewable power is inconsistent, the amount of green hydrogen produced by Nel’s electrolysers will vary. For this reason, the reactor holding the gases and catalysts required to synthesise green ammonia must be highly adaptable, or dynamic.

“The important thing is to maintain consistent temperature and pressure while the production rate varies,” says Pat Han, Technical Director at Skovgaard Energy. The pilot facility, set to enter operation by the end of 2023, will be able to stay in a standby state for up to a week. “That means we can restart the plant in 10 minutes. Otherwise it would take 10-12 hours from completely cold,” Han says.

This quick start-up time implies large cost savings. Han used to work at a conventional gas-fired plant in France, where it would take three days to restart operations at a cost of €500,000 (in 2012). Skovgaard Energy’s dynamic solution can be retrofitted to any existing ammonia plant, so such expense, waste and pollution are no longer necessary.

Cost-efficiency without exotic materials

The pilot plant is only about 1% of the size a commercially viable plant would be, but projections suggest that it would already be profitable to run a full-size operation, even if it only produced about 50% of its nominal capacity.

The metrics work out because the cost of the dynamic plant would be less than 2% higher than a conventional facility, and the overall cost of production per unit ammonia about half that incurred using natural gas at current prices. If this is the case in the absence of carbon taxes, then the profitability potential when punitive carbon pricing inevitably arrives is clear.

Han describes dynamic green-ammonia production as a “Columbus’ egg” idea: one that seems incredibly simple once someone has shown the ingenuity to realise it potential. Skovgaard Energy’s plans present a solution to the power-curtailment problem that, unlike the use of battery arrays, generates additional value and does not depend on the use of finite resources like lithium and cobalt.