With the official launch of the world’s first fully automated electrolyser production facility, Nel is near to making green hydrogen a true winner.

Green renewable hydrogen currently makes up just one percent of the world’s total industrial and mobility hydrogen consumption. But Nel’s pioneering new plant at Herøya, which is officially opened today, is at the forefront of the race to turn one into one hundred. In addition, falling cost of green hydrogen will unlock new application areas where green hydrogen is the best or only option for decarbonizing.

“Nel’s new factory at Herøya is a step in the right direction towards a future without emissions.”

– Terje Lien Aasland, Norwegian Minister of Energy and Petroleum

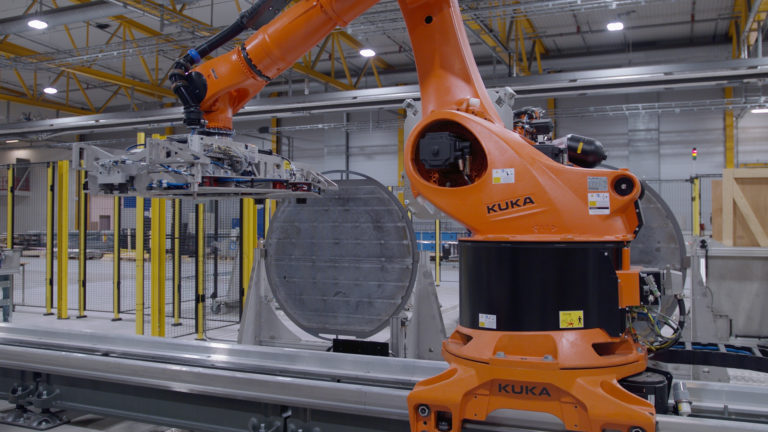

The secret is scale-up and automation, which is lowering the unit cost of electrode production like never before. Nel is on track to make green renewable hydrogen as cheap, or cheaper, to produce than natural-gas-based hydrogen by 2025.

Nel is reiterating its goal of delivering green hydrogen at $1.5/kg*, and to achieve this capex must be reduced to a quarter of today’s level.

Scaling up and increasing efficiency

“Half of the savings we need to make will come from scale-up and increased efficiency in production. The rest will come from the economy of scale, and from effective industrial partnerships,” says Jon André Løkke, Nel’s CEO.

“At Herøya we are producing the best alkaline electrolysers in the world. The next step would be to industrialize our PEM technology in the US in a similar way,” says Løkke, adding that Nel is also investing a lot of capital in the development of concepts as large as 800 MW and beyond based on 20, 100, 200 MW building blocks.

“Our large-scale concepts allow us to optimize the overall capex and realize synergies to reduce cost”, says Løkke.

Made in Norway

Nel has invited customers and partners for the grand opening of the new factory, and the Norwegian Minister of Energy and Petroleum will give the official opening speech.

“Nel’s new factory at Herøya is a step in the right direction towards a future without emissions. In a growing hydrogen market, even more electrolysers are needed, and it will be a sign of quality that the electrolysers are marked «Made in Norway»”, says Terje Lien Aasland, Minister of Energy and Petroleum. “Norway has competitive and competent industrial environments that can contribute to hydrogen development. Not least at Herøya.”

Nel is the leading electrolyser company in the world with a track record of large-scale projects, making solutions that are bankable with proven performance guarantees. In fact, the two largest electrolyser plants in Europe are currently being finalized with Nel’s technology.

This pioneering new plant at Herøya currently has 500 MW of production capacity. With further investment, this figure can rise to 2 GW, a sizeable portion of the 10 GW of capacity Nel is targeting to reach within 2025, if required by the market.