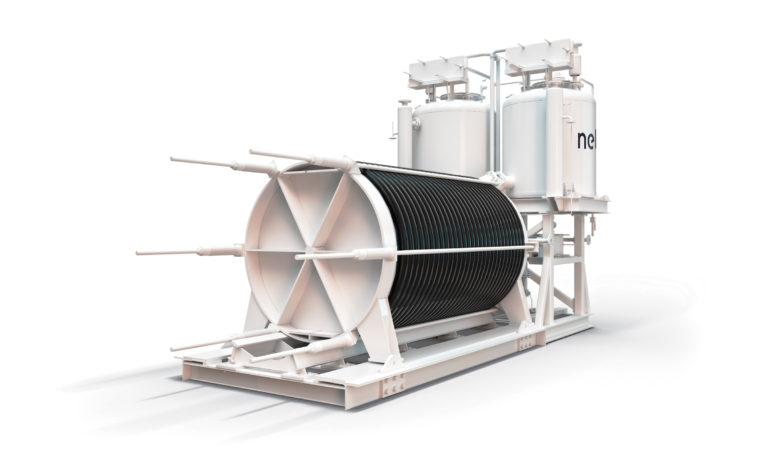

Nel’s water electrolysers will help you reduce your operating costs, eliminate the need for delivered hydrogen, streamline your operations, and increase your bottom line. By producing hydrogen on-demand, they can also eliminate the need for stored hydrogen, saving valuable floor space and increasing plant safety. When connected to a source of renewable energy, these electrolysers will produce green hydrogen, reducing your plant’s carbon footprint and impact on the environment.

Contact us for a free consultation with one of our sales engineers today.

When determining which generator will suit your operation best, the important criteria to define is the following:

When purchasing a gas generator, one must consider:

All electrolysis-based hydrogen generators require deionized water and electricity. Nel offers water deionizing systems for all our electrolyzer products. Power requirements range from a few hundred Watts for small electrolyzers, to > 1 MW for larger systems.

Delivered gases and cylinders are heavy, cumbersome and often troublesome. Delivered gas supply can be irregular, causing disruptions in production. Bottled gases are also subject to fluctuating prices. If you are in a remote location, bottled gas delivery can also be very costly. On-site gas generation is a safe and cost effective solution to traditional gas supply methods.

Nel hydrogen generators contain minimal hydrogen inventory, well below NFPA, and contain an amount far below safety concern in a ventilated space.